What is AFFF foam?

AFFF (Aqueous Film Forming Foam) is a fluorine-containing firefighting foam primarily used to extinguish flammable liquids such as petrol. It forms a water film between the flammable liquid and the foam, and this allows the foam to spread easily and knock down the flames quickly. A synthetic foam concentrate is mixed with water and aerated through a foam nozzle to generate the foam. AFFF contains fluorosurfactants (PFAS), some of which are banned or will be banned due to their environmentally harmful and toxic properties.

Will AFFF be banned?

The short answer: Yes, AFFF will most likely be banned due to the PFAS (Per- and Polyfluorinated Alkyl Substances) they contain. The EU Commission wrote

“The Commission will ban all PFAS as a group in firefighting foams [..], allowing their use only where they are essential for society.”

European Commission 2020: Chemicals Strategy for Sustainability – Towards a Toxic-Free Environment

However, at present, fluorinated foams can still be used if they meet certain limits. So far, only individual PFAS have been regulated, rather than fluorine-containing foam concentrates as a group. Currently, these are PFOS, PFOA, and C9-14 PFCA. In the future, further substances are expected to be banned (particularly PFHxS and PFHxA). Each of these substances has its own limit values and its own transition periods for use in foam concentrate. Since this is a bit complicated, I wrote an article just about the PFAS ban in foam concentrate.

How does AFFF work?

Before we look at how AFFF extinguishes, let’s see how foam works in principle.

Water is not suitable for extinguishing a burning liquid such as gasoline. It has a higher density than most fuels and would sink below the liquid surface rather than extinguish it. Foam has a lower density than fuel, so it stays on top and can extinguish the fire.

Foam consists of water, a foaming agent and air. Synthetic foam concentrates contain surfactants to create foam. These are molecules with a water-loving (hydrophilic) end and a water-repellent (hydrophobic) end. In the water, they try to arrange themselves so that one part of the molecule is in the water while the other part does not come into contact with the water. So they collect on the water surface and stretch the hydrophobic part into the air. This happens until the surface is occupied. When air is mixed with the water and foam concentrate, it forms a foam because there is a much larger surface area, and more surfactants can align with one part in the aqueous foam wall (lamella) and the other part in the air bubble.

The surfactants in conventional synthetic foam concentrates are called hydrocarbon surfactants because the molecules are largely made up of carbon and hydrogen atoms. AFFF also contains fluorosurfactants, and most of the hydrogen atoms in these molecules have been replaced by fluorine atoms. And that makes an important difference. The hydrophobic part of a hydrocarbon surfactant simultaneously attracts oils and fats (it is lipophilic). The hydrophobic part of a fluorosurfactant is also lipophobic, meaning it repels oils and fats. By the way: No other common surfactant has an hydrophobic part that is also lipophobic. This is why PFAS-based foams are so hard to replace.

So how do these two types of surfactants arrange themselves on the surface of an oil (the fuel)? The hydrocarbon surfactants dip into the oil with their lipophilic end while the other (hydrophilic) end sticks out. The fluorosurfactants also tend to seek an aqueous environment with their water-loving, hydrophilic part, while the other end is repelled by both fuel oil and water – and therefore sticks out in the air. Therefore, a very thin water film is formed between these two types of surfactants. And although water has a higher density than oil, the water film “floats” on top. Because of this water film, the foam is called Aqueous Film Forming Foam (AFFF).

Why is AFFF so good?

The water film formed by the AFFF offers some key advantages. It limits the evaporation of fuel by imposing a barrier to mass transfer. In addition, it spreads very quickly and enables the foam floating on it to spread rapidly. This allows the flames to be extinguished quickly and the foam to reach more distant areas, even in a very large fire. If the applied foam is torn open, the water film ensures that the hole closes again quickly.

Another positive effect is the reduction of the so-called fuel pick-up effect. This occurs when the foam plunges into the fuel when it is applied and absorbs fuel in the process. The fuel can destroy the foam. The lipophobic property of the fluorosurfactants forces the fuel out of the foam, making it less susceptible to destruction by the fuel pick-up effect.

The formation of a water film distinguishes AFFF from other foams, especially fluorine-free foams. It also makes it possible for the foam to function with relatively poor expansion – i.e. a low ratio of air to foam concentrate/water mixture. The stability of the foam is also not as important because it is necessary for the water to drain off the foam to form it. Therefore, AFFF often has a relatively short drainage time. It only takes a few minutes for half of the mass of the foam concentrate/water mixture originally used to drain out of the foam.

The undemanding nature of the AFFF in terms of expansion is an advantage, for example, when used in extinguishing systems. Sprinklers are not optimised for the use of foam. However, with AFFF, it is still possible to design an extinguishing system with foam proportioning and classic sprinklers. Until a few years ago, AFFFs were the only foam concentrates intended for use in extinguishing systems. Only the growing awareness of the environmental problems of PFAS in AFFF led to the increased use of other fluorine-free foam concentrates.

Is AFFF harmful to the environment?

The fluorosurfactants needed for the water film of the AFFF are also generally referred to as PFAS (per- and polyfluorinated alkyl substances). This is a group of thousands of substances in which all the hydrogen atoms on at least one carbon atom have been replaced by fluorine atoms.

The term PFC (per- and polyfluorinated chemicals) is also sometimes used for PFAS. PFAS are problematic because they do not degrade in nature or only degrade to other PFAS. This property is called persistence. In addition, some PFAS accumulate in an organism (e.g. in a fish or the human body). Therefore, the concentration of PFAS in the fish increases, e.g. through food intake, and they are not completely excreted. This is called bioaccumulation, which can lead to biomagnification if the PFAS are passed up the food chain when you eat a fish. In addition to persistence and bioaccumulation, there is another concern of many PFAS: they are toxic. PFAS are said to have several health effects. These include e.g.

- Changes in antibody responses to vaccines

- Changes to lipid and cholesterol levels

- Changes in offspring birth weight

From research with animals, known effects are

- Damage to the liver

- Changes in the timing of puberty

- Changes to hormone levels

Substances with the three properties of persistence, bioaccumulation, and toxicity are also referred to as ‘PBT substances’. Some – but not all – PFAS fall into this category and have therefore been or will be regulated. However, the properties of persistence and bioaccumulation are already a concern. The toxicity of PFAS can sometimes only be proven with effort and can take a lot of time. However, by then, persistent and bioaccumulative substances have long been in the environment and cannot be retrieved.

When was AFFF invented?

AFFF was developed in the 1960s by the American Naval Research Laboratory and the chemical company 3M and was finally patented in 1966. In 1967, a fire broke out aboard the aircraft carrier USS Forrestal, leading to 134 sailors lost. An electrical malfunction accidentally launched a missile on the aircraft carrier’s flight deck. It hit the fuel tank of another parked fighter jet. The leaking fuel caught fire, setting off a chain reaction by igniting other planes and especially bombs, which then exploded. Some lessons about firefighting were learned from this disaster. Untrained crews used water to extinguish the fire with good intentions, but in doing so, they destroyed the foam already applied by other crews. As a consequence, the US Navy introduced AFFF as a foam concentrate on all of its ships. Over the years, the foam concentrate was introduced to other areas. It became the standard foam concentrate for military, airports, refineries, and chemical industries. But many municipal fire brigades also introduced the fluorine-containing foam as the “best of the best”.

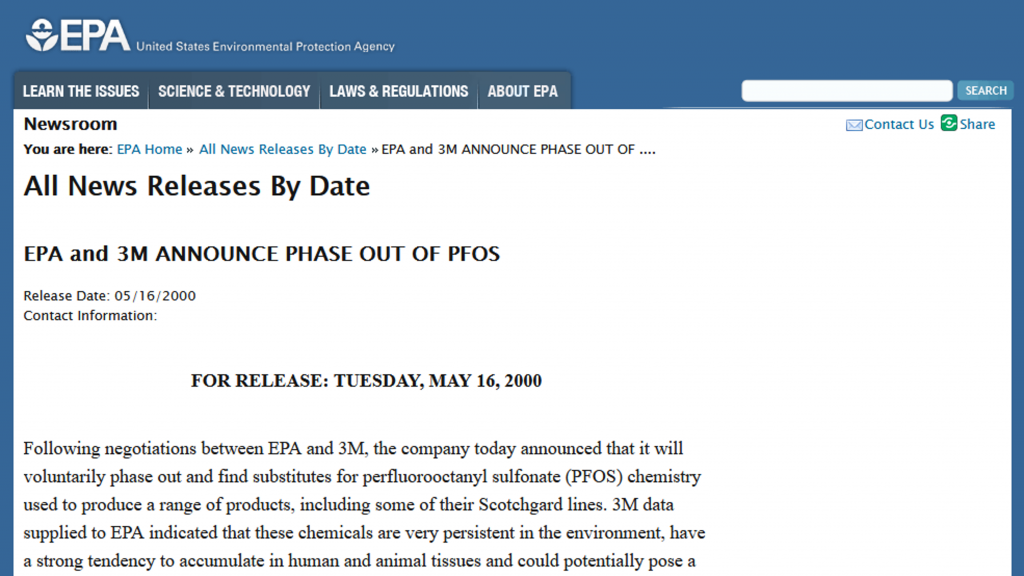

The success of the AFFF lasted three decades until the American Environmental Protection Agency (EPA) and the manufacturer 3M announced the end of PFOS (perfluorooctane sulfonic acid) in 2000. Until then, PFOS had been the main active ingredient for AFFF, and so people in the fire service community wondered where this end of production came from. The users of fluorine-containing foam concentrates only gradually became aware of the environmental problems of this substance. On the other hand, the manufacturer had been aware of these problems for some time.

AFFF for aircraft firefighting

The advantages of AFFF always came into play when a short extinguishing time was important or when there was a risk from very large fires. Aircraft firefighting was one of the applications. The scenario of a fully occupied aircraft engulfed in flames is relatively rare but is nevertheless catastrophic. The aircraft can only withstand a fire for a few minutes. A very fast extinguishment time is important. The so-called ICAO test (described in Doc 9137/AN/898 of the International Civil Aviation Organization) designed for fighting aircraft fires requires an extinguishing time of one minute. If a fire tray of a certain size can be extinguished within that one minute, the foam concentrate is rated A, B, or C, depending on the size of the fire tray. AFFF is still the most widely used extinguishing agent for aircraft firefighting worldwide. However, in recent years high-performance fluorine-free foam concentrates, which receive a B or C rating according to the ICAO standard, have also been developed for aircraft firefighting. Several major international airports have already successfully switched to fluorine-free foam concentrates.

AFFF in refineries and the chemical industry

Other fields where AFFF is often used are refineries and the chemical industry. Here the foam is used for all fires involving flammable liquids (as an alcohol-resistant AFFF for polar fuels, of course). The main concern is tank fires because large storage tanks and their containment areas can be several thousand square meters in size and require a good performing foam. If a tank fire is extinguished by a fire brigade using only mobile technology, this is usually done with large foam-water monitors. They allow large throw distances, but at the same time, this direct application leads to fuel pick-up. The oil-repellent properties of AFFF reduce this effect. In fact, it has long been considered to be irreplaceable for tank firefighting for the chemical industry as a whole. However, many tests, especially by organisations such as Lastfire, have shown that modern fluorine-free foam concentrates are quite capable of extinguishing even very large tank fires.